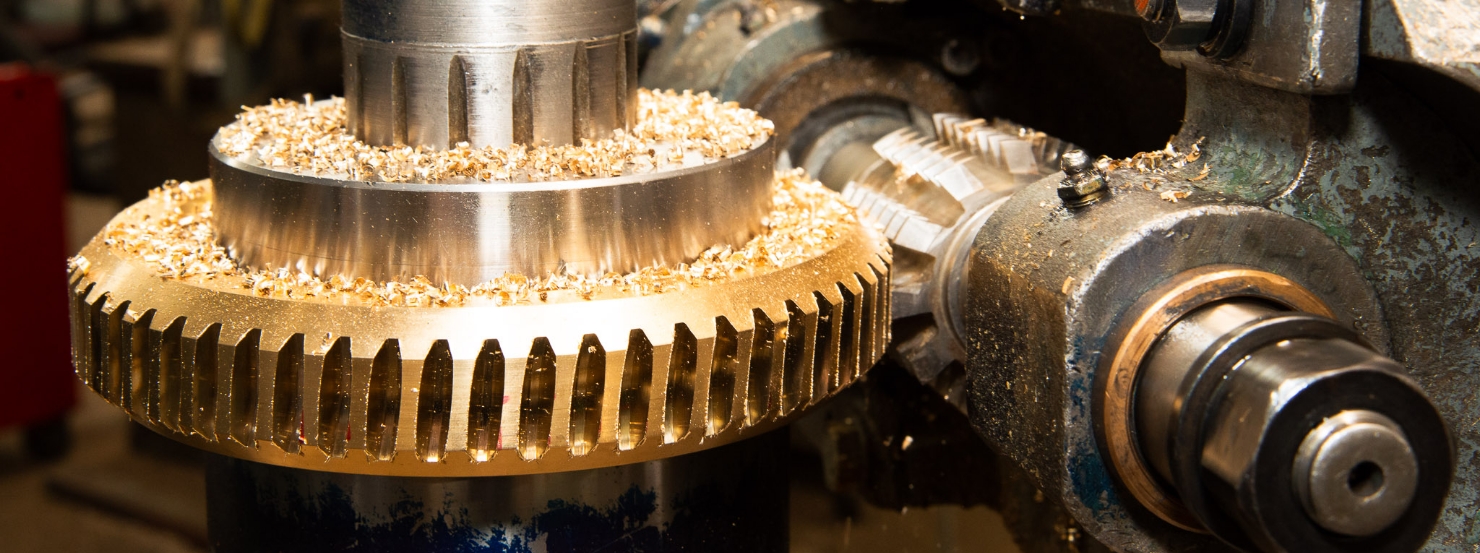

MACHINING

Fast, high-precision machining of gears, splines, pulleys, sprockets, keyways and more

From experts with unmatched machining experience and capabilities

So you can save money through maximizing part and system longevity

THE BENEFITS

Grooving and graphite plugging

Keyways and broaching

Gear cutting specialists

YOUR GEAR EXPERTS

All gears types and custom work in metric & DP

We can provide every kind of gear — spur, helical, worm (including shaft), bevel (spiral and regular), splines (internal/external), plus timing pulleys, sprockets, ratchets and pawls. We work with both metric and DP (diametrical pitch). Common varieties are our bread and butter, but we love precise, custom work.

Our team is proficient in all essential machining techniques

Expert Machining Services

Specialized grooving, graphite plugging & CNC production

We also offer specialized grooving and graphite plugging services. We can advise on the best lubrication and design options, including internal and external diameter, that will extend the useful working life of your machines.

Because we have both manual and CNC machinery, we can cost-efficiently deliver both short- and long-run production batches. Bar stock feeding automation further improves our CNC lathe productivity.

Precision Threading & Keyway Cutting

Specialty threads, keyways, and broaching services

We can identify and create specialty and unique threads. We also offer external and internal keyway cutting in sizes of up to 2.5″, including blind keyways. Our broaching service is second to none for precision machining. We offer high-tolerance linear and rotary broaching designed to meet your specific needs.

CASE STUDY

Custom gears for joint COVID-19 Relief Project

Bearing Headquarters played a small but key role in helping to generate critically needed vials for the storage of COVID-19 vaccines and therapeutics.

While many medical supply companies stepped up to manufacture vials, one decided to develop faster, automated precision machinery to increase production. Bearing Headquarters was part of a team of top industrial manufacturers and vendors that made it happen.

Our role was to provide highly-specialized, custom-made gears, enlisting one of our BHQ specialty shops — Gear Headquarters — to accelerate production. The Gear HQ team immediately began getting extra raw materials shipped in overnight and manufactured two fixtures to facilitate a speedy production. The effort meant the first batch of 160 pieces was dispatched in only four days, and more shipments followed just days later.

We boast exceptional skills in the following fields

Gear Shaping • Gear Hobbing • Turning • Milling • Key Broaching • Grinding

We work with all types of machining equipment

Mori Seiki • Haas • Mazak • Helios • Bridgeport • Acer • Summit

added value

Other services that make your work easier

Emergency breakdown

24/7 help to repair your equipment.

Failure analysis

If your machinery is not running properly and you don’t know why, our engineers can pinpoint the cause.

Support and training

Our reps love to share their expertise and solve problems. Where very specialized training is needed, we involve relevant OEMs or other specialists.

Kitting and assemblies

We can kit items as specified to complete a job, do a segment of a job, complete a portion of a shipment to your customer or supply as a repair kit.

Expediting

When you need it fast, we can make it happen.

Bearing interchange guide

The quickest and simplest way to find valid interchanges for any bearing.

VMI

We can help with some (or maybe all) of your inventory and storeroom management.

Bar coding

We bar code in your preferred format using the latest equipment, and label to your specifications. This includes packing slips, invoices, individual items and containers.